Kab lus no yuav qhia txog cov tswv yim tsim thiab kev ua cov txheej txheem ntawm cov yas noj su lub thawv npog kom ntxaws, thiab cov qauv ntawm cov khoom yas, cov ntaub ntawv rau kev tsom xam, tsim nyog tsim cov tshuab pwm.

Cov lus tseem ceeb: txhaj tshuaj pwm;Noj su box.Moulding txheej txheem

Tshooj 1: Kev soj ntsuam ntawm cov khoom yas thiab thawj xaiv ntawm lub tshuab txhaj tshuaj

1.1Cov ntaub ntawv raw thiab kev soj ntsuam kev ua tau zoo ntawm cov yas noj su lub thawv

Lub thawv yas noj su no yog cov khoom siv yas hauv lub neej txhua hnub, feem ntau yog siv los tuav cov khoom noj.Xav txog qhov tshwj xeeb ntawm nws cov kev siv, kev tsom xam ntawm kev ua tau zoo ntawm ntau yam yas, kev xaiv cov khoom siv rau polypropylene (PP).

Polypropylene (PP yas) yog ib hom kev kub ceev, tsis muaj sab saw, siab crystallization ntawm linear polymer, muaj cov khoom zoo heev.Thaum tsis muaj xim, dawb translucent, waxy;Lub teeb dua polyethylene.Transparency kuj zoo dua li polyethylene.Tsis tas li ntawd, qhov ceev ntawm polypropylene yog me me, lub ntiajteb txawj nqus ntawm 0.9 ~ 0.91 grams / cubic centimeter, yield zog, elasticity, hardness thiab tensile, compressive zog yog siab tshaj polyethylene.Nws molding kub yog 160 ~ 220 ℃, tuaj yeem siv li ntawm 100 degrees, thiab muaj cov khoom siv hluav taws xob zoo thiab cov hluav taws xob ntau zaus tsis cuam tshuam los ntawm cov av noo.Nws cov dej nqus dej yog qis dua polyethylene, tab sis yooj yim rau yaj lub cev rupture, ntev kev sib cuag nrog cov hlau kub yog yooj yim rau decompose, laus.Lub fluidity yog qhov zoo, tab sis qhov sib sau shrinkage tus nqi yog 1.0 ~ 2.5%, tus nqi shrinkage yog loj, uas yog ib qho yooj yim ua rau lub shrinkage qhov, dent, deformation thiab lwm yam tsis xws luag.Polypropylene txias ceev yog ceev ceev, pouring system thiab txias system yuav tsum tau maj mam txias, thiab xyuam xim rau kev tswj qhov kub thiab txias.Cov phab ntsa tuab ntawm cov yas yuav tsum tsis sib xws kom tsis txhob muaj cov kua nplaum thiab lub kaum ntse ntse kom tiv thaiv kev ntxhov siab.

1.2Kev tshuaj xyuas cov txheej txheem molding ntawm lub thawv noj su

1.2.1.Kev txheeb xyuas cov qauv ntawm cov khoom yas

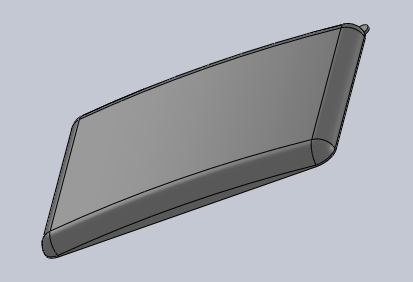

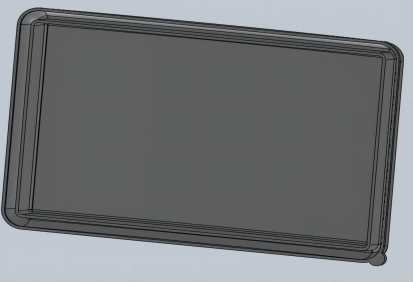

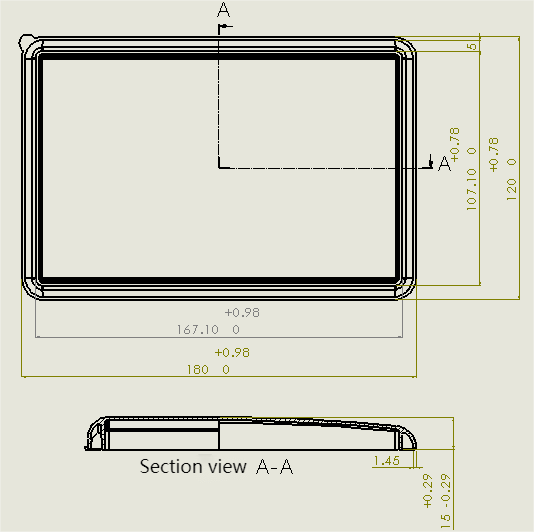

Qhov pom zoo phab ntsa thickness ntawm polypropylene me me yas qhov chaw yog 1.45mm;Qhov loj me ntawm lub thawv noj su yog 180mm × 120mm × 15mm;Siv cov phab ntsa sab hauv ntawm lub thawv noj su: 107mm;Qhov sib txawv ntawm cov phab ntsa sab hauv thiab sab nrauv yog: 5 hli;Lub kaum sab xis ntawm phab ntsa sab nrauv yog 10 hli, thiab lub kaum sab xis ntawm phab ntsa sab hauv yog 10/3 hli.Ib lub ces kaum ntawm lub thawv npog muaj ib tug thawj annular nrog ib lub vojvoog ntawm 4 hli.Vim hais tias cov khoom yas yog nyias-walled ntim, txhawm rau tiv thaiv qhov tsis muaj qhov tawv thiab lub zog los ntawm cov khoom yas deformation, yog li sab saum toj ntawm cov khoom yas yog tsim los ua 5 hli siab arc lub voj voog.

1.2.2.Dimensional precision tsom xam ntawm cov khoom yas

Ob qhov ntev ntawm lub thawv noj su muaj qhov yuav tsum tau ua, uas yog 107mm thiab 120mm, thiab qhov yuav tsum tau muaj tseeb yog MT3.Txij li thaum sab nraud ntawm cov khoom yas yog cuam tshuam los ntawm kev kam rau siab ntawm qhov ntev ntawm qhov txav tau ntawm cov pwm (xws li cov npoo ya), hom kev kam rau siab raug xaiv raws li qib B. Yog tias tsis xav tau qib siab, MT5 raug xaiv. .

1.2.3.Surface zoo tsom xam ntawm cov khoom yas

Qhov tseeb saum npoo ntawm lub npov noj su tsis siab, thiab qhov roughness Ra yog 0.100 ~ 0.16um.Yog li ntawd, ib qho kev sib cais ntawm qhov kab noj hniav txhaj tshuaj pwm ntawm lub rooj vag khiav tuaj yeem siv los xyuas kom meej qhov raug.

1.2.4 ib.Cov khoom siv thiab ntim thiab zoo ntawm cov khoom yas

Nug cov khoom siv ntawm PP yas (xws li elastic modulus, Poisson tus piv, ntom, nro lub zog, thermal conductivity thiab tshwj xeeb kub) hauv SolidWorks, thiab siv SolidWorks software los xam cov ntaub ntawv ntawm cov khoom yas (xws li qhov hnyav, ntim, qhov chaw thiab qhov chaw. ntawm lub ntiajteb txawj nqus).

1.3 Txheeb xyuas cov txheej txheem molding tsis ntawm cov khoom yas

Nyob rau hauv cov txheej txheem ntawm kev txhaj tshuaj molding, qhov kub ntawm lub tog raj kheej thiab lub nozzle yuav cuam tshuam rau plasticization thiab ntws ntawm cov yas, qhov kub ntawm cov pwm yuav cuam tshuam rau kev khiav thiab txias ntawm cov yas shaping, lub siab nyob rau hauv cov txheej txheem ntawm kev txhaj tshuaj molding yuav ncaj qha cuam tshuam rau cov khoom siv molding. plasticization ntawm cov yas thiab yas qhov zoo.Kev tsim khoom nyob rau hauv cov ntaub ntawv ntawm kev ua kom zoo ntawm cov khoom yas yuav sim ua kom luv lub voj voog molding ntawm cov khoom yas, uas lub sij hawm txhaj tshuaj thiab lub sij hawm txias muaj qhov cuam tshuam rau qhov zoo ntawm cov khoom yas.

Cov lus nug yuav tsum xav txog thaum tsim:

1) Tsim nyog siv cov stabilizers, lubricants los xyuas kom meej cov txheej txheem ntawm PP yas thiab siv cov khoom yas.

2) Shrinkage, indentation, deformation thiab lwm yam tsis xws luag yuav tsum tau tiv thaiv thaum tsim.

3) Vim yog lub cua txias ceev ceev, xyuam xim rau lub tshav kub dissipation ntawm lub pouring system thiab cua txias system, thiab xyuam xim rau kev tswj ntawm qhov kub thiab txias.Thaum cov pwm kub qis dua 50 degrees, cov khoom yas yuav tsis du, yuav muaj vuam tsis zoo, tawm hauv cov cim thiab lwm yam tshwm sim;Ntau tshaj 90 degrees yog feem ntau rau warp deformation thiab lwm yam tshwm sim.

4) Cov phab ntsa tuab ntawm cov yas yuav tsum tsis sib xws kom tsis txhob muaj kev ntxhov siab.

1.4 Qauv thiab specification ntawm kev txhaj tshuaj molding tshuab

Raws li cov txheej txheem molding tsis ntawm cov khoom yas, thawj qhov kev xaiv ntawm domestic G54-S200/400 qauv txhaj tshuaj molding tshuab,

Qhov thib ob: Cov qauv tsim ntawm lub thawv ntim khoom noj khoom haus yas npog txhaj tshuaj pwm

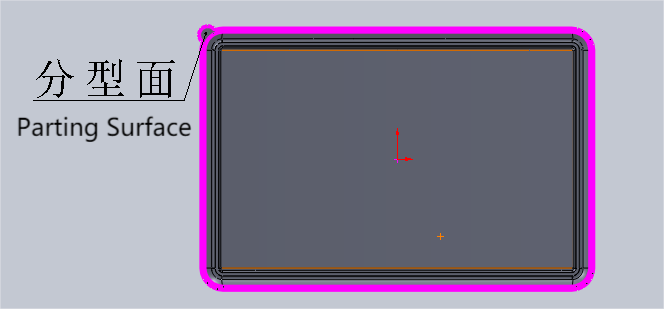

2.1 Kev txiav txim siab ntawm qhov chaw parting

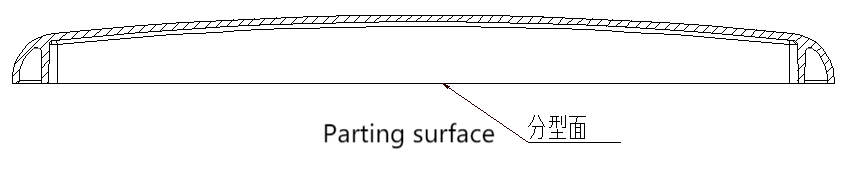

Qhov yooj yim cov duab thiab demoulding mob ntawm cov khoom yas yuav tsum tau txiav txim siab thaum xaiv qhov chaw seem.Cov qauv tsim ntawm qhov chaw parting yog raws li nram no:

1. Lub parting nto yuav tsum tau xaiv ntawm qhov siab tshaj plaws contour ntawm cov yas

2. Kev xaiv ntawm qhov chaw sib cais yuav tsum ua kom zoo rau kev ua kom zoo ntawm cov khoom yas

3. Kev xaiv ntawm qhov sib cais yuav tsum xyuas kom meej qhov tseeb thiab qhov zoo ntawm cov khoom yas thiab lawv cov kev siv.

4. Kev xaiv ntawm qhov chaw sib cais yuav tsum ua kom zoo rau kev ua thiab ua kom yooj yim ntawm cov pwm

5. Txo qhov projection cheeb tsam ntawm cov khoom nyob rau hauv cov kev taw qhia ntawm clamping

6. Cov tub ntxhais ntev yuav tsum tau muab tso rau hauv kev taw qhia ntawm qhov qhib tuag

7. Kev xaiv ntawm qhov chaw sib cais yuav tsum ua kom muaj kev tso pa tawm

Txhawm rau ua kom tiav, txhawm rau txhawm rau txhawm rau ua kom du ntawm cov khoom yas thiab cov kev xav tau ntawm cov khoom yas thiab kev tsim cov pwm yooj yim, cov khoom seem raug xaiv raws li qhov qis ntawm lub thawv noj su.Raws li pom hauv daim duab hauv qab no:

2.2 Cavity tooj txiav txim thiab configuration

Raws li cov qauv tsim ntawm cov khoom siv yas tsim phau ntawv, cov khoom siv yas geometric qauv cov yam ntxwv thiab cov kev xav tau ntawm qhov tseeb thiab kev lag luam ntawm kev tsim khoom, txiav txim siab siv cov pwm kab noj hniav.

2.3 Tsim cov txheej txheem pouring

Qhov kev tsim no siv cov txheej txheem pouring zoo tib yam, thiab nws cov qauv tsim muaj raws li hauv qab no:

Khaws cov txheej txheem luv luv.

Cov pa taws yuav tsum zoo,

Tiv thaiv cov tub ntxhais deformation thiab ntxig hloov chaw,

Tiv thaiv cov warping deformation ntawm cov khoom yas thiab tsim cov caws pliav txias, qhov chaw txias thiab lwm yam tsis xws luag ntawm qhov chaw.

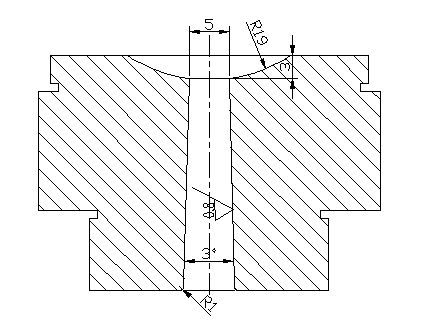

2.3.1 Main channel tsim

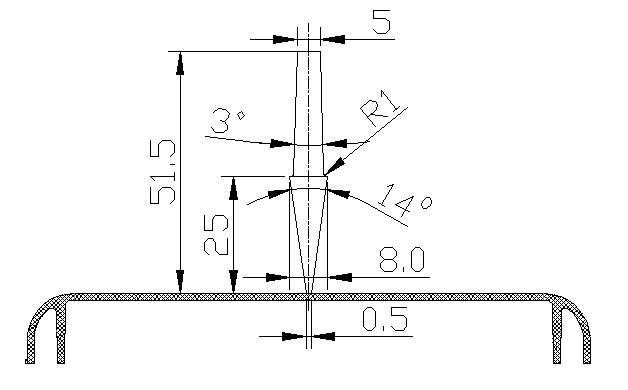

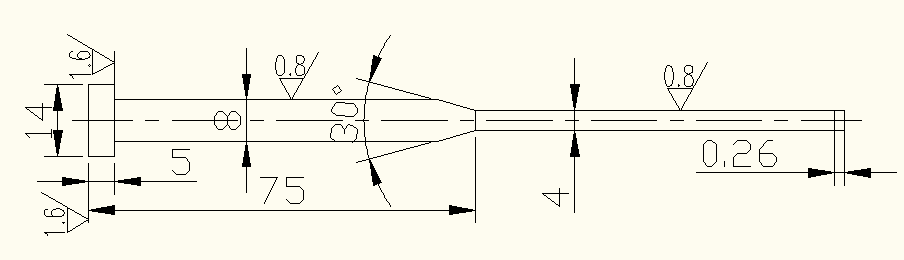

Lub ntsiab channel yog tsim los ua conical, thiab lub khob hliav qab α yog 2O-6O, thiab α = 3o.Qhov saum npoo roughness ntawm qhov ntws channel Ra≤0.8µm, qhov hluav taws xob ntawm lub ntsiab channel yog kev hloov pauv, txhawm rau txo qhov tsis kam ntawm cov khoom ntws mus rau qhov kev hloov pauv, lub vojvoog fillet r = 1 ~ 3mm, yog siv li 1 hli. .Lub ntsiab channel tsim yog raws li nram no;

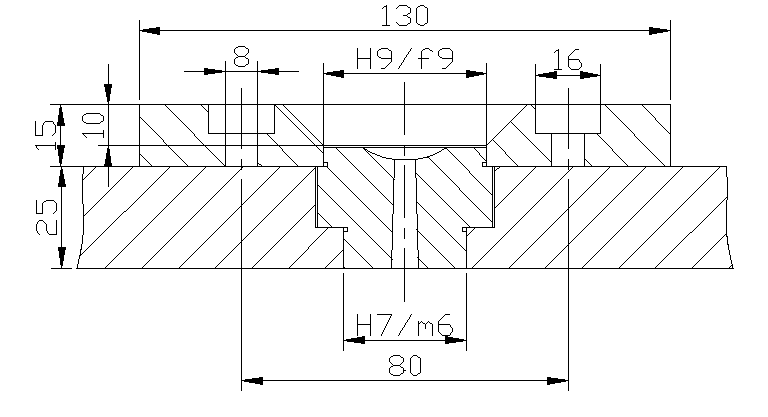

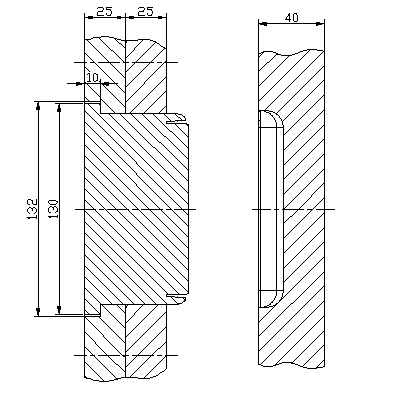

Cov qauv ntawm lub rooj vag lub tes tsho yog tsim los ua ob feem siv lub tes tsho lub rooj vag thiab lub nplhaib muab tso rau, uas yog tsau rau ntawm lub rooj zaum tuag tas hauv daim ntawv ntawm ib kauj ruam.

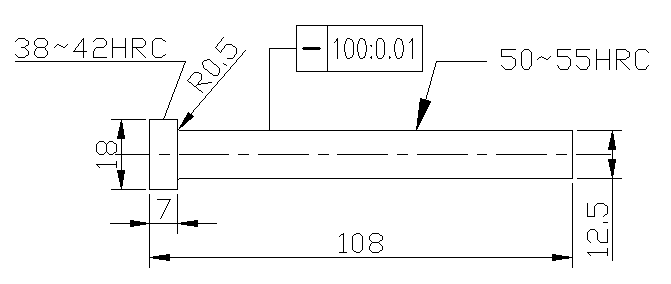

Txoj kab uas hla ntawm qhov kawg me me ntawm lub tes tsho rooj vag yog 0.5 ~ 1mm loj dua li ntawm lub nozzle, uas yog coj li 1 hli.Txij li thaum lub hauv ntej ntawm qhov kawg me me yog ib tug kheej kheej, nws qhov tob yog 3 ~ 5 hli, uas yog coj li 3 hli.Txij li lub kheej kheej ntawm lub nozzle ntawm lub tshuab txhaj tshuaj tiv tauj thiab haum cov pwm ntawm txoj haujlwm no, txoj kab uas hla ntawm lub voj voog ntawm lub ntsiab channel yuav tsum yog 1 ~ 2 hli loj dua li ntawm lub nozzle, uas yog siv li 2 hli.Daim ntawv siv thiab qhov ntsuas ntawm lub tes tsho rooj vag yog qhia hauv qab no:

H7 / m6 hloov pauv haum yog saws nruab nrab ntawm lub tes tsho rooj vag thiab cov qauv, thiab H9 / f9 haum yog saws nruab nrab ntawm lub rooj vag lub tes tsho thiab lub nplhaib tso.Lub nplhaib muab tso rau hauv qhov chaw ntawm qhov chaw ruaj khov ntawm lub tshuab txhaj tshuaj thaum lub sijhawm teeb tsa thiab kev debugging ntawm pwm, uas yog siv rau kev teeb tsa thiab qhov chaw ntawm lub pwm thiab lub tshuab txhaj tshuaj.Sab nraud txoj kab uas hla ntawm lub nplhaib positioning yog 0.2 hli me dua li qhov chaw nyob ntawm lub taag template ntawm lub tshuab txhaj tshuaj, yog li nws yog 0.2 hli.Daim ntawv ruaj khov ntawm lub tes tsho lub rooj vag thiab qhov loj ntawm lub nplhaib muab tso rau hauv qab no:

2.3.2 Shunt channel tsim

Vim hais tias tus tsim yog ib tug pwm kab noj hniav, parting nto rau hauv qab ntawm lub thawv npog, thiab lub rooj vag xaiv rau lub point gate ncaj hom, yog li shunt tsis tas yuav tsim.

2.3.3 Lub rooj vag tsim

Xav txog cov molding yuav tsum tau ntawm cov yas qhov chaw thiab pwm ua yog yooj yim los yog tsis thiab qhov tseeb siv ntawm qhov teeb meem, yog li ntawd tus tsim ntawm lub rooj vag qhov chaw yog xaiv raws li qhov chaw saum toj kawg nkaus ntawm lub rooj noj mov cover.Txoj kab uas hla ntawm lub rooj vag taw tes yog feem ntau 0.5 ~ 1.5mm, thiab yog coj li 0.5 hli.Lub kaum sab xis α feem ntau yog 6o ~ 15o, thiab yog coj li 14o.Tus tsim ntawm lub rooj vag yog qhia hauv qab no:

2.4 Tsim lub qhov txias thiab rub pas nrig

Yog li ntawd, tus tsim yog pwm thiab kab noj hniav, taw tes rooj vag ncaj qha pouring, yog li lub qhov txias thiab rub pas nrig yuav tsum tsis txhob tsim.

2.5 Tsim cov khoom tsim

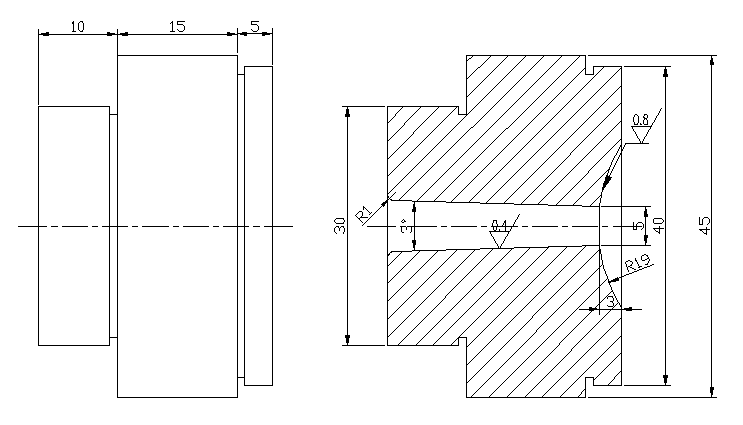

2.5.1Kev txiav txim siab ntawm kev tuag thiab punch qauv

Vim tias nws yog cov yas me me, kab noj hniav, thiab txhawm rau ua kom muaj kev ua haujlwm siab, yooj yim disassembly, tab sis kuj los xyuas kom meej cov duab thiab qhov loj ntawm cov khoom yas, qhov tsim ntawm tag nrho convex thiab concave tuag xaiv rau tag nrho.Lub convex tuag yog ua tiav los ntawm txoj kev sib cais, thiab tom qab ntawd nias rau hauv cov qauv nrog H7 / m6 hloov.Lub schematic daim duab ntawm tus qauv tsim ntawm lub convex thiab concave tuag yog raws li nram no:

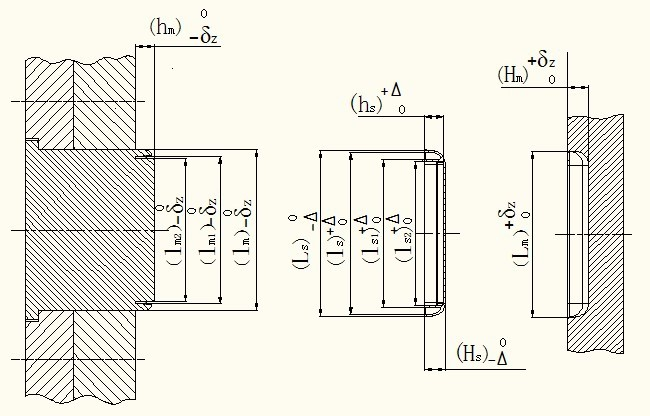

2.5.2Tsim thiab suav cov kab noj hniav thiab cov qauv tseem ceeb

Kev sib raug zoo ntawm kev ua hauj lwm loj ntawm cov pwm thiab cov yas qhov loj yog qhia hauv qab no:

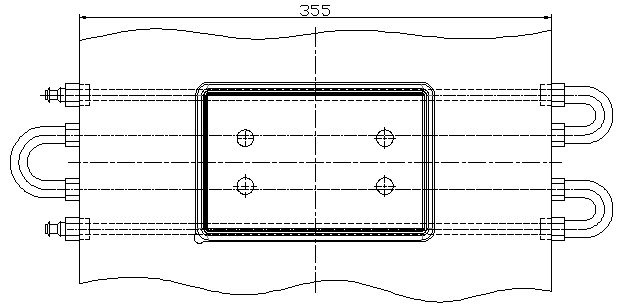

2.6 Kev xaiv ntawm pwm ncej

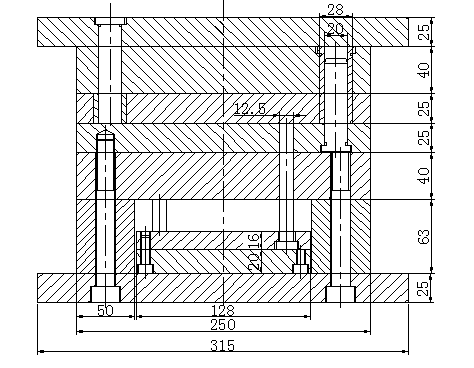

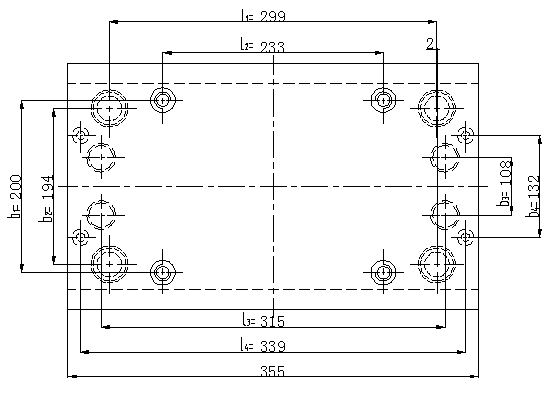

Txij li qhov tsim no yog rau cov yas me me thiab nruab nrab, cov pwm pwm yog P4-250355-26-Z1 GB / T12556.1-90, thiab B0 × L ntawm cov pwm pwm yog 250mm × 355mm.

Daim duab sib dhos pwm yog raws li nram no:

2.7 Cov qauv tsim qauv

2.7.1 ibQhia kem qauv tsim

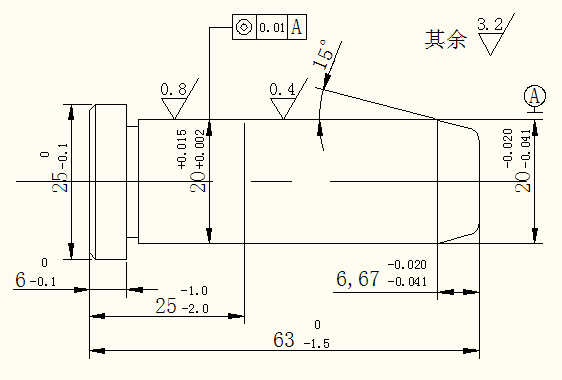

Txoj kab uas hla ntawm daim ntawv qhia yog Φ20, thiab cov khoom xaiv rau cov ntawv qhia yog 20 steel, nrog carburizing ntawm 0.5 ~ 0.8 hli thiab quenching hardness ntawm 56 ~ 60HRC.Lub chamfered lub kaum sab xis qhia hauv daim duab tsis ntau tshaj 0.5 × 450.Daim ntawv qhia ntawv yog cim raws li Φ20 × 63 × 25 (I) - 20 steel GB4169.4 - 84. H7 / m6 kev hloov pauv haum tau txais los ntawm qhov chaw ruaj khov ntawm kab lus qhia thiab cov qauv.Lwm phau ntawv qhia yog cim Φ20 × 112 × 32 — 20 steel GB4169.4 — 84.

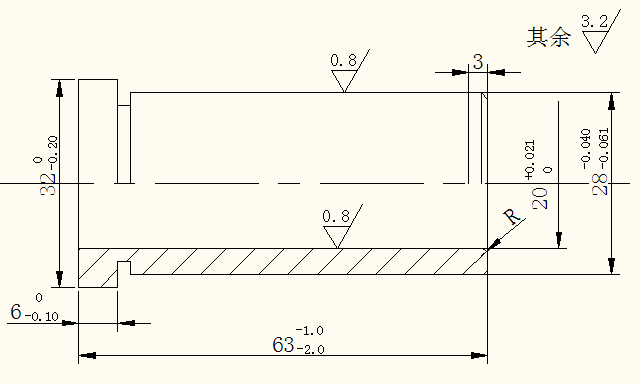

2.7.2Qhia lub tes tsho qauv tsim

Txoj kab uas hla ntawm lub tes tsho qhia yog Φ28, thiab cov khoom ntawm lub tes tsho qhia yog 20 steel, carburized 0.5 ~ 0.8mm, thiab hardness ntawm quenched kev kho mob yog 56 ~ 60HRC.Lub chamfering qhia nyob rau hauv daim duab yog tsis ntau tshaj 0.5 × 450.Lub tes tsho qhia yog cim raws li Φ20 × 63 (I) - 20 steel GB4169.3 - 84, thiab qhov sib txuam ntawm cov lus qhia thiab lub tes tsho qhia yog H7 / f7.Lwm lub tes tsho qhia cim Φ20 × 50 (I) — 20 steel GB4169.3 — 84.

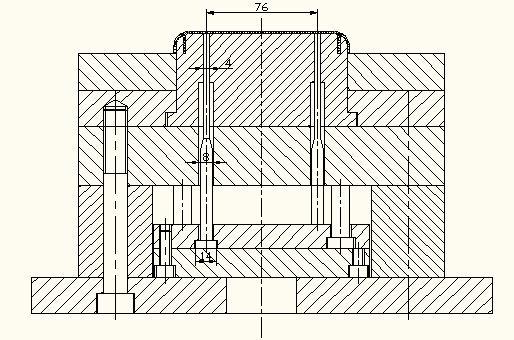

2.8 Launch mechanism tsim

Lub tshuab thawb feem ntau yog tsim los ntawm kev thawb, rov pib dua thiab kev taw qhia.

Vim hais tias cov khoom yas yog cov nyias nyias, nyob rau hauv cov ntaub ntawv ntawm kev sim xyuas kom meej qhov zoo ntawm cov yas qhov chaw, tus tsim ntawm lub launcher mechanism txais lub ejector pas nrig los thawb tawm cov yas qhov chaw.

Lub schematic daim duab ntawm lub launching mechanismyog raws li nram no:

Cov qauv thiab qhov ntsuas ntawm lub laub pas nrigyog qhia hauv qab no:

Cov txheej txheem daim ntawv thiab tsis ntawm tus pas nrig pib duayog qhia hauv qab no:

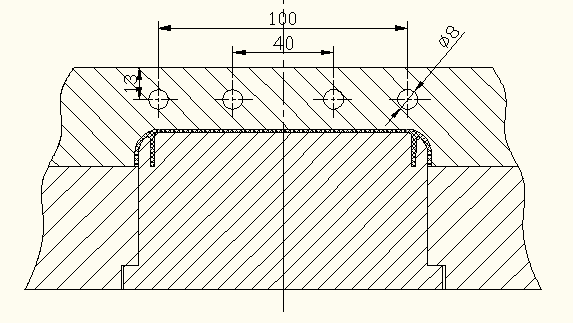

2.9 Tsim cov cua txias system

Raws li cov cua txias tsis sib xws, cov cua txias ntawm cov cua txias channel yuav tsum muaj ntau npaum li qhov ua tau, qhov kev xaiv tsim no rau 4. Qhov kev ncua deb ntawm cov kab noj hniav ntawm cov kab noj hniav yog sib npaug, thiab cov sprue kuj ntxiv dag zog rau cov cua txias.Lub tshuab ua kom txias txais DC ncig hom, uas muaj cov qauv yooj yim thiab ua haujlwm yooj yim.

Lub tshuab cua txias tsim yog raws li nram no:

Tshooj 3: Tshawb xyuas kev txhaj tshuaj pwm

3.1.Kuaj xyuas cov txheej txheem tsis zoo ntawm lub tshuab txhaj tshuaj

3.1.1 Txheeb xyuas qhov ntim siab tshaj plaws

3.1.2 Txheeb xyuas lub zog clamping

3.1.3 Txheeb xyuas cov pwm qhib kev mus ncig

3.2.Tshawb xyuas lub thickness ntawm sab phab ntsa thiab hauv qab phaj ntawm cov kab noj hniav

3.2.1 Txheeb xyuas cov phab ntsa tuab ntawm cov kab noj hniav sib dhos

3.2.2 Txheeb xyuas qhov tuab ntawm cov kab noj hniav hauv qab phaj

xaus

Freshness Keeper pab pawg tus tsim Xie Master qhov kev tsim no yog tsim rau cov pwm tsim ntawm cov yas noj su lub thawv npog, los ntawm kev txheeb xyuas cov khoom siv ntawm cov yas noj su lub thawv npog, cov qauv ntawm cov khoom yas thiab cov tshuab, thiab tom qab ntawd tsim nyog, kev tshawb fawb tiav ntawm kev txhaj tshuaj pwm. tsim.

Freshness Keeper Qhov zoo ntawm kev tsim qauv yog ua kom yooj yim rau kev txhaj tshuaj molding tshuab kom deb li deb tau los xyuas kom meej qhov zoo ntawm cov khoom yas, ua kom lub voj voog molding, txo cov nqi tsim khoom.Cov ntsiab lus tseem ceeb ntawm kev tsim qauv yog cov txheej txheem txhaj tshuaj molding, kab noj hniav layout, parting nto xaiv, gating system, ejection mechanism, demoulding mechanism, txias system, txhaj tshuaj molding tshuab xaiv thiab xyuas cov tsis muaj feem xyuam thiab tsim ntawm lub ntsiab qhov chaw.

Freshness Keeper qhov tshwj xeeb tsim nyob rau hauv kev tsim cov txheej txheem pouring, pouring system lub rooj vag lub tes tsho thiab tso lub nplhaib rau ib feem, xyuas kom lub neej ntawm pwm, thiab cov khoom xaiv, kev ua, kev kho cua sov thiab hloov tau yooj yim;Lub rooj vag yog taw tes rooj vag ncaj hom, uas yuav tsum tau muab ob npaug rau qhov chaw, thiab qhov kev ncua deb drawplate yog siv los txwv cov thawj parting.Cov qauv yog yooj yim thiab tsim nyog.

Post lub sij hawm: Nov-01-2022